What Is Calendering

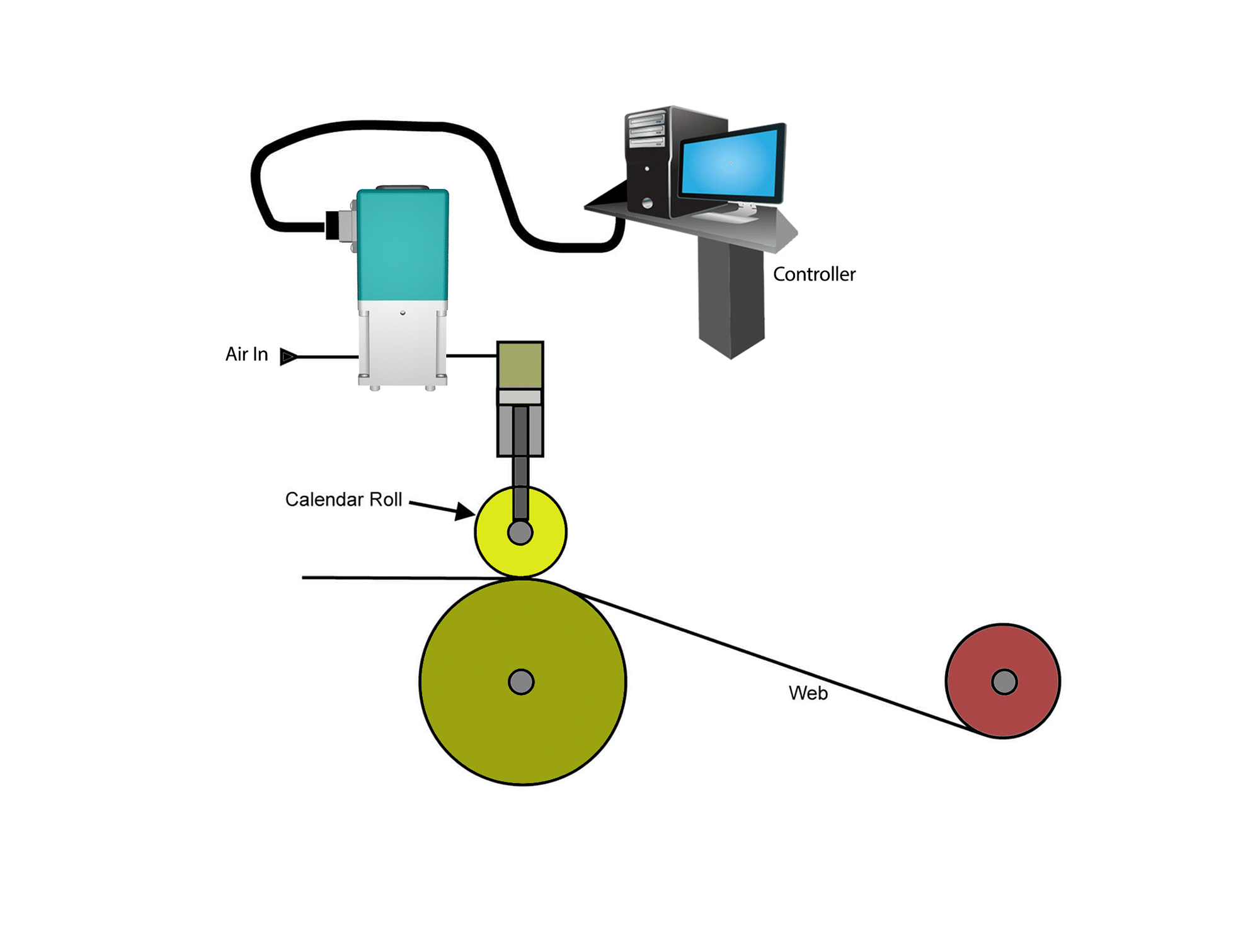

What Is Calendering - This molten plastic then moves through a series of heated rollers that. This is a manufacturing process used in industries like papermaking, textiles, and plastics. A calendering process is a finishing operation used in various industries, particularly in the textile, paper, and plastic industries, to impart specific properties to materials. It involves passing materials through a series of rollers (a calender) to smooth,. Calendering is a mechanical process that directs siliconerubber or other plastics such as pvcs or vinyl (and even paper or textiles), through single or multiple pairs of heated. The primary goal is to create a smooth, glossy surface on.

The primary goal is to create a smooth, glossy surface on. Calendering is a mechanical process that directs siliconerubber or other plastics such as pvcs or vinyl (and even paper or textiles), through single or multiple pairs of heated. Calendering is a mechanical process used to improve the surface characteristics of materials, particularly textiles and rubber. A calendering process is a finishing operation used in various industries, particularly in the textile, paper, and plastic industries, to impart specific properties to materials. In calendering, raw materials enter a mixing chamber where they are melted.

A calendering process is a finishing operation used in various industries, particularly in the textile, paper, and plastic industries, to impart specific properties to materials. Calendering is a mechanical process used to improve the surface characteristics of materials, particularly textiles and rubber. This molten plastic then moves through a series of heated rollers that compress the. Calendering is the process.

Calendering is a process whereby fabric is compressed by passing it between two or more rollers under controlled conditions of time, temperature and pressure in order to alter its handle,. Rubber calendering is a rubber processing process. Sync with your calendar and create focused time slots to achieve your goals. The primary purpose is to alter the fabric's surface. Calendering.

It involves passing materials through a series of rollers (a calender) to smooth,. With the simultaneous action of temperature, force and moisture, the surface of the textile substrate are modified. Calendering is the process of pressing a continuous web or substrate, such as cloth, rubber, paper, film, nonwoven, composite, wire mesh, etc., between rollers to create. Calendering is a mechanical.

This molten plastic then moves through a series of heated rollers that compress the. Calendering is a mechanical process used to improve the surface characteristics of materials, particularly textiles and rubber. A calendering process is a finishing operation used in various industries, particularly in the textile, paper, and plastic industries, to impart specific properties to materials. In calendering, raw materials.

With the simultaneous action of temperature, force and moisture, the surface of the textile substrate are modified. The primary purpose is to alter the fabric's surface. This simultaneous action is called calendering. Calendering is a mechanical finishing process that involves passing fabric through a series of heated rollers under high pressure. Experience a planning tool that helps you concentrate on.

What Is Calendering - The primary purpose is to alter the fabric's surface. This molten plastic then moves through a series of heated rollers that. In calendering, raw materials enter a mixing chamber where they are melted. Rubber calendering is a rubber processing process. Calendering is a mechanical process used to improve the surface characteristics of materials, particularly textiles and rubber. The primary goal is to create a smooth, glossy surface on.

This forms a rubber sheet or film of the desired shape and. This molten plastic then moves through a series of heated rollers that. The primary goal is to create a smooth, glossy surface on. Calendering is a process whereby fabric is compressed by passing it between two or more rollers under controlled conditions of time, temperature and pressure in order to alter its handle,. With the simultaneous action of temperature, force and moisture, the surface of the textile substrate are modified.

Calendering Is A Mechanical Process That Directs Siliconerubber Or Other Plastics Such As Pvcs Or Vinyl (And Even Paper Or Textiles), Through Single Or Multiple Pairs Of Heated.

Calendering is a process whereby fabric is compressed by passing it between two or more rollers under controlled conditions of time, temperature and pressure in order to alter its handle,. The primary purpose is to alter the fabric's surface. Calendering is a mechanical process used to improve the surface characteristics of materials, particularly textiles and rubber. This forms a rubber sheet or film of the desired shape and.

In Calendering, Raw Materials Enter A Mixing Chamber Where They Are Melted.

Calendering is a mechanical finishing process that involves passing fabric through a series of heated rollers under high pressure. Rubber calendering is a rubber processing process. Sync with your calendar and create focused time slots to achieve your goals. Calendering is the process of pressing a continuous web or substrate, such as cloth, rubber, paper, film, nonwoven, composite, wire mesh, etc., between rollers to create.

This Molten Plastic Then Moves Through A Series Of Heated Rollers That.

This molten plastic then moves through a series of heated rollers that compress the. Experience a planning tool that helps you concentrate on what matters most. This simultaneous action is called calendering. It involves passing materials through a series of rollers (a calender) to smooth,.

In Calendering, Raw Materials Enter A Mixing Chamber Where They Are Melted.

A calendering process is a finishing operation used in various industries, particularly in the textile, paper, and plastic industries, to impart specific properties to materials. This is a manufacturing process used in industries like papermaking, textiles, and plastics. The primary goal is to create a smooth, glossy surface on. With the simultaneous action of temperature, force and moisture, the surface of the textile substrate are modified.